Incorrect calculation of sling load is one of the most common causes of lifting accidents.

Many people assume that the force on a lifting sling is simply equal to the weight of the object being lifted—but in reality, the tension acting on a sling is often far greater than the weight of the load itself.

This article breaks down how sling load is calculated, what factors affect sling tension, and how to avoid the most common mistakes in actual lifting operations.

1. What Is A Lifting Sling Load?

Lifting sling load refers to the actual force applied to each sling leg during a lifting operation.

Key point to remember: Sling load ≠ Load weight

The load acting on a sling depends on:

- Lifting angle

- Number of sling legs

- Center of gravity

- Hitch type (vertical, choker, basket)

Ignoring these factors can result in sling overload—even when the load weight is within the rated capacity.

Impact of Sling Configuration on Load Distribution

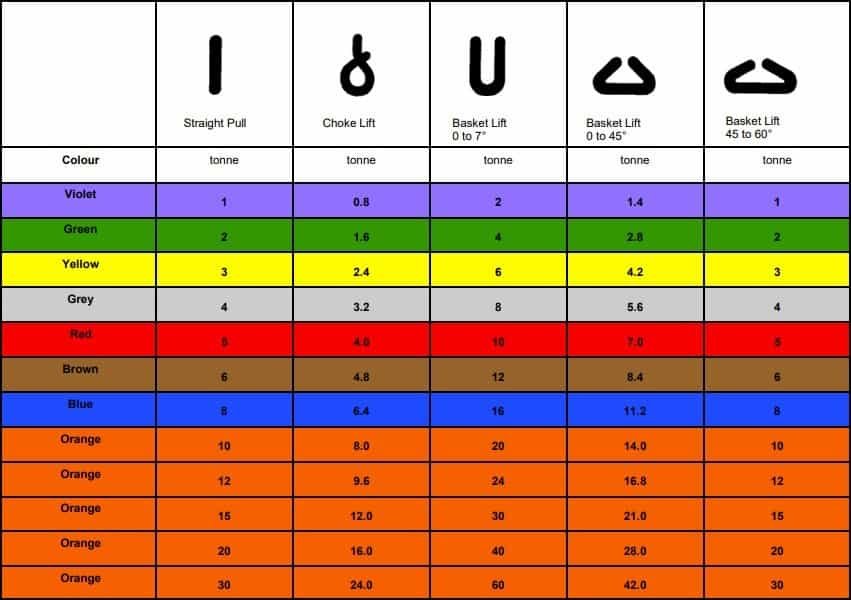

Different sling configurations significantly affect how the load is distributed. The table below summarizes the key characteristics and precautions for four common rigging methods:

| Configuration | Load Characteristics | Efficiency / Capacity | Key Considerations |

|---|---|---|---|

| Vertical Lift | Sling tension = Load weight | Most efficient | Ensure vertical alignment of lifting points and avoid side sway |

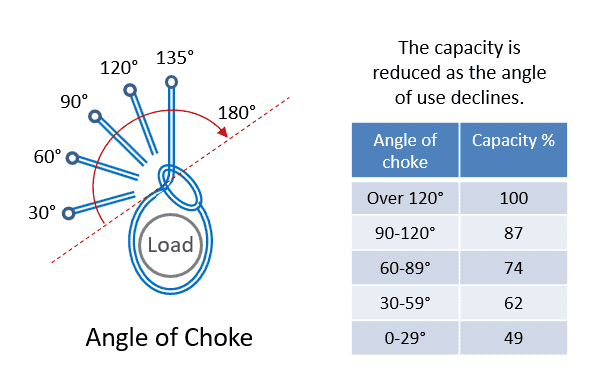

| Choker Hitch | Load concentrates at the choke point | Rated capacity is typically 80% of the vertical WLL | Check wear at the choke point; sling condition is critical |

| Basket Hitch | Load is shared between two sling legs | Actual capacity depends heavily on the sling angle | Smaller angles increase sling tension; maintain load balance |

| Multi-leg Sling | Load is rarely evenly distributed | A single leg may carry significantly more than its theoretical share | Always use an equalizer and design for the maximum possible single-leg load |

- Except for the vertical lift, all other configurations reduce the sling’s theoretical load capacity.

- Sling angle and load balance are the two most critical variables in actual operations.

- Always select slings based on the maximum possible single-leg load, not just the calculated average.

Sling Angle: The Most Critical Factor

One of the biggest mistakes in lifting is ignoring the sling angle.

Why Sling Angle Matters

As the sling angle decreases, the tension in each sling leg increases dramatically.

Smaller angle = higher sling load

Typical Sling Angle Factors

| Sling Angle | Tension Factor |

|---|---|

| 90° | 1.00 |

| 60° | 1.15 |

| 45° | 1.4 |

| 30° | 2.00 |

At a 30° angle, each sling leg carries twice the load weight.

More Lifting Points, Less Load Per Sling? Not Always.

A common—but risky—assumption in rigging is:

*“Two slings share the load equally — 50/50.”*

In practice, it rarely works out that cleanly.

Why? Because even slight variations can shift most of the weight onto one sling:

- Slight differences in sling length

- Off‑center lifting points

- The stiffness or shape of the load itself

That’s why safety standards for 3‑leg and 4‑leg sling arrangements often operate on a conservative rule: unless you can prove equal sharing, assume only two legs are carrying the full load.

In short: more slings don’t mean less load per sling — they mean you must plan for imbalance.

Common Sling Load Calculation Mistakes

Here are the most frequent errors seen on job sites:

- Ignoring the sling angle

- Assuming equal load sharing

- Using a choker hitch without capacity reduction

- Lifting from incorrect points

- Ignoring dynamic forces during lifting

Avoiding these mistakes can prevent serious accidents.

Conclusion

Correct lifting sling load calculation is not complicated—but it must be done properly.

Remember:

- Sling load is influenced by angle, configuration, and real conditions

- Always calculate based on the worst-case scenario

- Safety margins save lives and equipment

A few minutes spent on proper calculation can prevent costly failures and serious injuries.

评论

发表评论