In the world of modern logistics and warehousing, the Hand Pallet Truck—also known as a manual pallet jack—is one of the most widely used and essential tools for material handling. Known for its simplicity, reliability, and cost-effectiveness, it plays a vital role in short-distance transportation across warehouses, factories, supermarkets, and more.

What is a hand pallet truck?

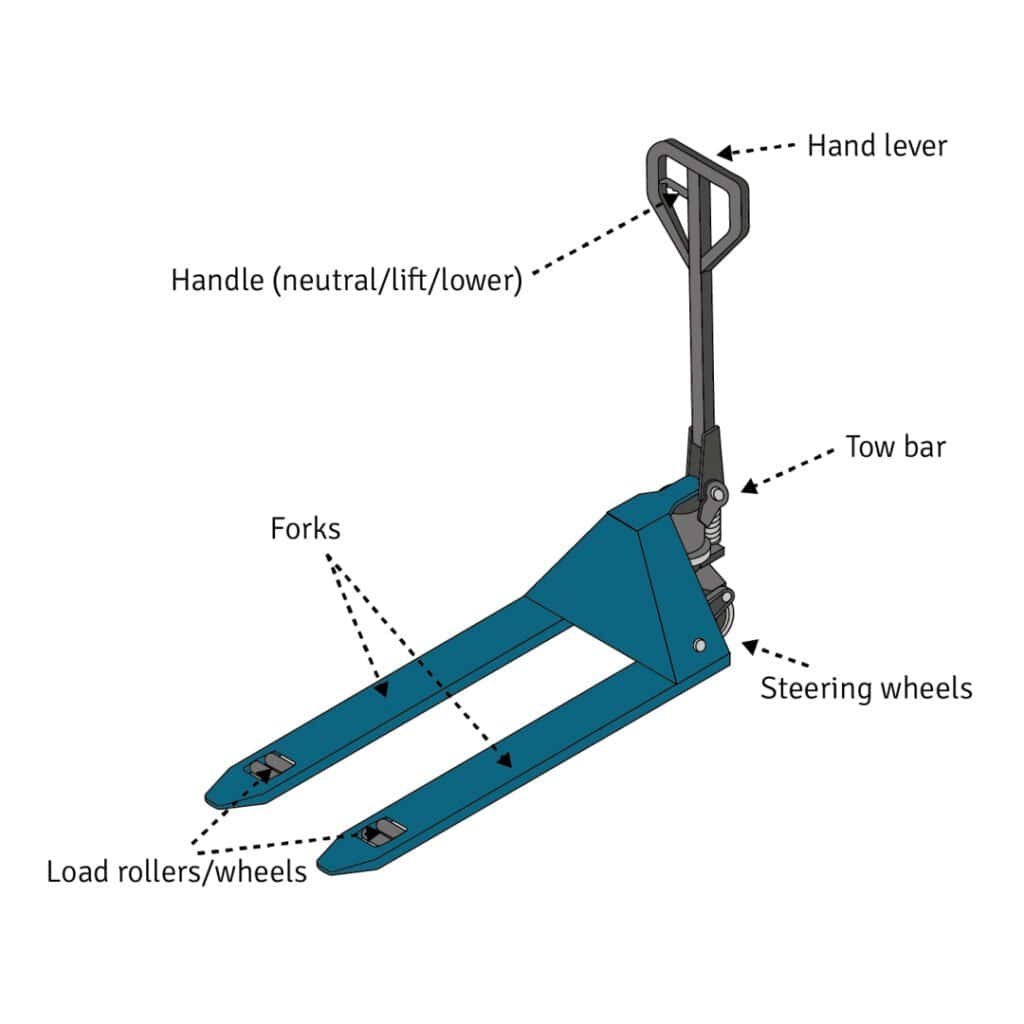

A hand pallet truck is a manually operated tool used to lift and move palletized loads. It typically consists of:

- Handle – for steering and controlling the hydraulic pump.

- Hydraulic pump – activated by pressing the handle up and down to raise or lower the forks.

- Fork arms – slide into the base of a pallet and support the load.

- Wheels – front and rear wheels made of materials like nylon, PU, or rubber, depending on the environment.

Common Application Scenarios

Due to its easy operation and versatility, the hand pallet truck is widely used in:

- Warehouses and storage centers

- Supermarket restocking

- Factory workshops

- Loading and unloading areas

- Cold storage or cleanrooms (stainless steel models)

It is ideal for short-distance, low-height movement on flat surfaces and serves as a cost-effective alternative to forklifts.

How to Choose the Right Pallet Truck?

Choosing the right hand pallet truck depends on several key factors:

1. Load capacity

Common options include 2000kg, 2500kg, or 3000kg. Always match the truck to your typical load weight.

2. Fork size

The standard fork length is 1150mm, width is 550mm. The wide fork length is 1220mm, width is 685mm.

3. Wheel material

- Nylon – low resistance and high durability for hard, smooth floors.

- PU (Polyurethane) – quiet, floor-friendly, ideal for indoor use.

- Rubber – offers strong grip, suitable for rougher surfaces.

4. Working environment

- For wet or corrosive environments, choose stainless steel.

- For weighing while transporting, choose a weighing model.

- For narrow areas, consider a short-fork version with a tight turning radius.

Operating & Maintenance Tips

Safe Operation:

- Watch your footing and stand clear of the fork area.

- Lift and lower loads smoothly to prevent sudden drops.

- Never exceed the rated load capacity.

Maintenance Advice:

- Check for oil leakage in the hydraulic system.

- Clean the wheels regularly to avoid blockages.

- Keep the forks and pump clean to prevent rust.

- Lubricate bearings and moving parts periodically.

Frequently Asked Questions (FAQ)

Q1: What should I do if the hydraulic pump stops lifting?

A: Check for oil leakage or air in the system. It may require an oil refill or seal replacement.

Q2: What’s the difference between PU wheels and nylon wheels?

A: PU wheels are quieter and ideal for indoor use; nylon wheels are harder and better for heavy-duty applications.

Conclusion

A reliable hand pallet truck is a simple yet powerful tool that can greatly improve your daily material handling efficiency while lowering labor intensity and cost.

www.chinatoplifting.com

tracy@chinatoplifting.com

评论

发表评论