In lifting operations, choosing the right sling is just as crucial as selecting the proper crane, shackle, or hook. Among synthetic lifting slings, round slings and flat webbing slings are the two most common types used on construction sites, in factories, warehouses, and equipment installation projects.

Both are made of high-strength polyester fibers, offering light weight, flexibility, and ease of handling. They also comply with international standards such as EN 1492, AS 1353/AS 4497, and WSTDA specifications.

However, they differ significantly in structure, performance, ideal applications, durability, and safety characteristics. This article provides a comprehensive comparison of round slings versus flat webbing slings, helping you understand their differences and choose the right sling for your specific lifting needs.

Round Sling VS. Flat Webbing Sling

The most important and fundamental difference between these two sling types is their load-bearing structure.

Round Sling Construction

- Inner core yarns bear the entire load.

- The outer sleeve serves only as protection.

- If the sleeve is damaged, the internal core might still be intact—but any sleeve tear must be treated as a serious warning.

Webbing Sling Construction

- The woven webbing body itself bears the load.

- Reinforced eyes provide extra strength at the lifting points.

- Wear and damage are visible on the surface, making inspection easier.

Strength, WLL, and Lifting Performance

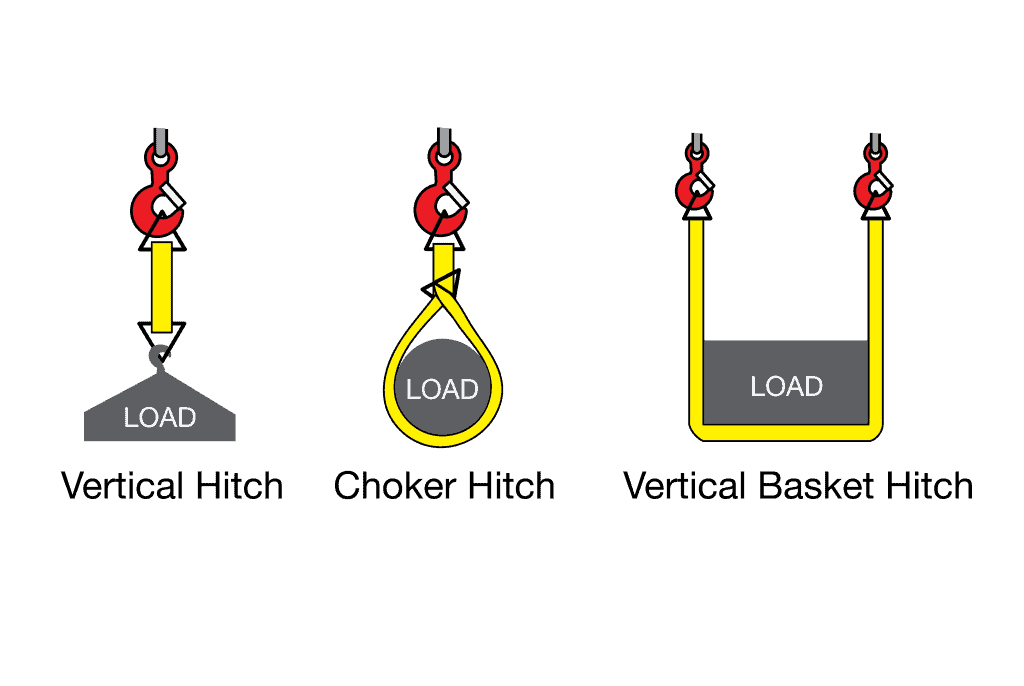

Both sling types follow similar color-coded WLL systems (e.g., purple 1T, green 2T, yellow 3T). However, their performance under various lifting methods can differ.

Round Sling Advantages

- Performs better in a choker (choke) hitch due to its circular shape.

- Wraps tightly and evenly around pipes, tubes, and machines.

- Lower risk of point loading.

Webbing Sling Advantages

- Provides a wider contact surface, distributing pressure more evenly on flat objects.

- Performs exceptionally well in a basket hitch, where the load is doubled.

- Less rolling movement because of its flat shape.

How to Choose the Right Sling?

You should choose a round sling if:

- The load has a curved or irregular shape

- The surface must not be scratched

- You frequently use the choker hitch

Choose a webbing sling if:

- The load is flat, boxed, or wide

- The sling may contact edges (with protectors)

A simple rule: Round sling for round objects; webbing sling for flat objects.

Final Thoughts

The choice between round slings and flat webbing slings often comes down to the task at hand. While both are indispensable in lifting operations, they each excel in specific situations. Round slings are valued for their flexibility and gentle handling of sensitive surfaces, while webbing slings stand out for their durability against abrasion, ease of inspection, and cost-effectiveness.

If your work regularly involves both flat and curved or irregular loads, it’s worth keeping both types on hand. That way, you’re always prepared with the right sling for the task.

评论

发表评论