How to quickly identify the tonnage of lifting slings? Detailed explanation of color coding and safety standards.

On construction sites, in ports, and across workshops, web slings and round slings are never mere accessories. With their distinctive, rainbow-like colors, they are a direct symbol of strength and safety. These colors are not for brightening up the industrial environment; they represent an internationally recognized “visual language” critical to the safety of life and property. Deciphering this color code is a mandatory course for every lifting professional.

Why Color Codes Matter: The Essential Role of the Lifting Sling System

When lifting heavy equipment, operators don’t have time to read small labels every time. In these situations, color becomes the most effective and immediate method of identification. The color of a lifting sling directly indicates its Working Load Limit (WLL), making it easy to quickly choose the right sling from a distance. This system helps prevent mistakes, ensuring safety and efficiency. Using a sling with a lower capacity is a risky mistake that could lead to disaster.

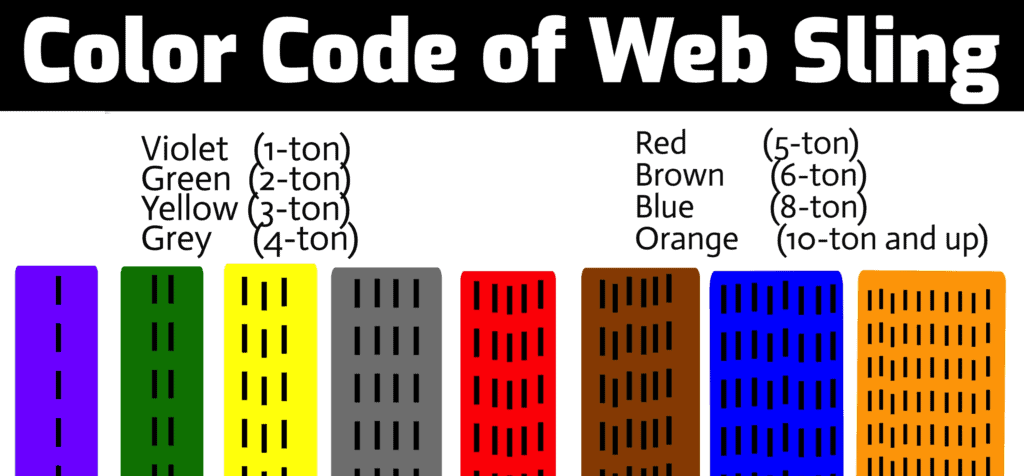

Decoding the Color Code: A Universal Guide

Currently, polyester lifting slings have established the most mainstream color-coding system worldwide. Below is the most common standard color code.

| Color | Working Load Limit (WLL) | Material | Common Applications |

|---|---|---|---|

| Purple | 1 Ton | Polyester | Lightest duties, precision instruments, electronic equipment, and small components. |

| Green | 2 Tons | Polyester | Light machinery, standard construction materials, and small equipment. |

| Yellow | 3 Tons | Polyester | High frequency of use for general lifting. |

| Grey | 4 Tons | Polyester | Medium-duty equipment, large machine tools, and medium steel structures. |

| Red | 5 Tons | Polyester | Heavy loads, large machinery, heavy steel structures, and industrial modules. |

| Brown | 6 Tons | Polyester | Heavier industrial applications, often in metallurgy and heavy equipment manufacturing. |

| Blue | 8 Tons | Polyester | Heavy lifting, common in ports, shipbuilding, and major engineering projects. |

| Orange | 10 Tons & Above | Polyester | Very heavy lifting, typically used in multi-leg configurations for massive loads. |

Beyond Color: The Label is the Legal “ID”

If color is the sling’s “appearance,” then the durable, stitched-on label is its unique, legally binding “identification card.”

We strongly advise and mandate: in all cases, “use color for initial selection, but always check the label for final confirmation.” The label provides unambiguous information:

- Working Load Limit (WLL): Clearly marked in tons or kilograms.

- Material: e.g., Polyester, which determines its characteristics.

- Compliance Standard: e.g., EN1492-2, ASME B30.9, indicating its manufacturing and testing norms.

- Manufacturer Info & Date: Essential for product traceability and service life.

Any sling with a damaged, missing, or illegible label should be immediately designated for “inspection” or “disposal.”

The Deeper Role of Color in Safety Practices

This color system plays a vital role in daily safety management and operations:

- Rapid Visual Inspection: Color helps quickly identify damage. For example, suppose a yellow (3-ton) sling is cut, revealing the white inner core fibers. In that case, this color contrast acts as a stark danger signal, indicating the sling is compromised and must be withdrawn from service immediately.

- Multi-Leg Lifting Assemblies: When using two, three, or four slings to lift a single load, the color code ensures operators can quickly and accurately match slings of equal capacity, guaranteeing even load distribution and preventing dangerous overload on a single leg.

- Addressing Fading and Aging: UV exposure, chemicals, and abrasion in industrial environments can cause slings to fade. A severely faded sling, whose original color is unidentifiable, has lost its coding function.

Conclusion: Color is a Tool, Safety is a Mindset

In summary, the color-coding system for lifting slings is an essential tool. It transforms abstract technical data into clear visual commands, serving as the first line of defense in safe lifting operations.

Master this color code. Make safety visible.

评论

发表评论