On construction sites, in warehouses, and across logistics operations, workers frequently handle heavy, bulky cylindrical objects such as concrete pipes and large drums. While they may appear similar in shape, their weight, surface characteristics, and handling requirements differ significantly—meaning the clamps designed for each are not interchangeable.

This article explains the definitions, structures, and typical applications of both concrete pipe clamps and drum clamps, highlights their key differences, and offers practical selection advice and safety tips to help you choose the right equipment for the job.

What Is a Concrete Pipe Lifting Clamp?

A cement pipe clamp is a lifting device designed specifically for handling concrete pipes. They are sold in sets of three, and they come complete with chain slings. They are designed for the vertical transportation of concrete pipe sections with a diameter of up to 2m.

Key Feature

- Factor of safety 4:1

- Solid construction

- Standard: DIN4034

- Pipe thickness of 40-220mm

| WLL (kgs) | Jaw-Capacity(mm) | Mouth Depth(mm) | Diameter of the chain |

| 1500 | 40-120mm | 165 | 6mm |

| 3000 | 50-180mm | 245 | 8mm |

| 3000 | 90-220mm | 245 | 8mm |

Typical applications:

- Pipe laying at construction sites

- Municipal drainage projects

- Tunnel construction and port loading/unloading

What Is a Drum Clamp?

A drum clamp is designed for handling steel drums, most commonly the standard 200L (55-gallon) type.

How many types of drum clamp?

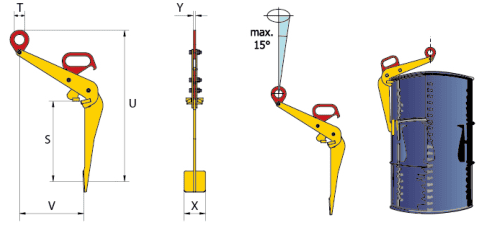

TDC Drum Clamps

The TDC drum clamp has been designed to lift and transport drums. If moving empty or sealed drums, then one clamp is sufficient on its own. If moving an open full drum, then two clamps should be used with a two-leg chain sling. It can be used with one or two pieces, both ok.

Load Capacity: 500kg, Jaw opening: 0-17mm

TDV Drum Clamp

The TDV drum clamp has been designed to lift and transport drums in the vertical position. One clamp can be used to lift drums with or without their lids by gripping the rim of the drum.

The Centre of gravity of the drum is the lifting point during transportation. The TDV is also available with a “lock on/open latch”.

Load capacity: 600kg

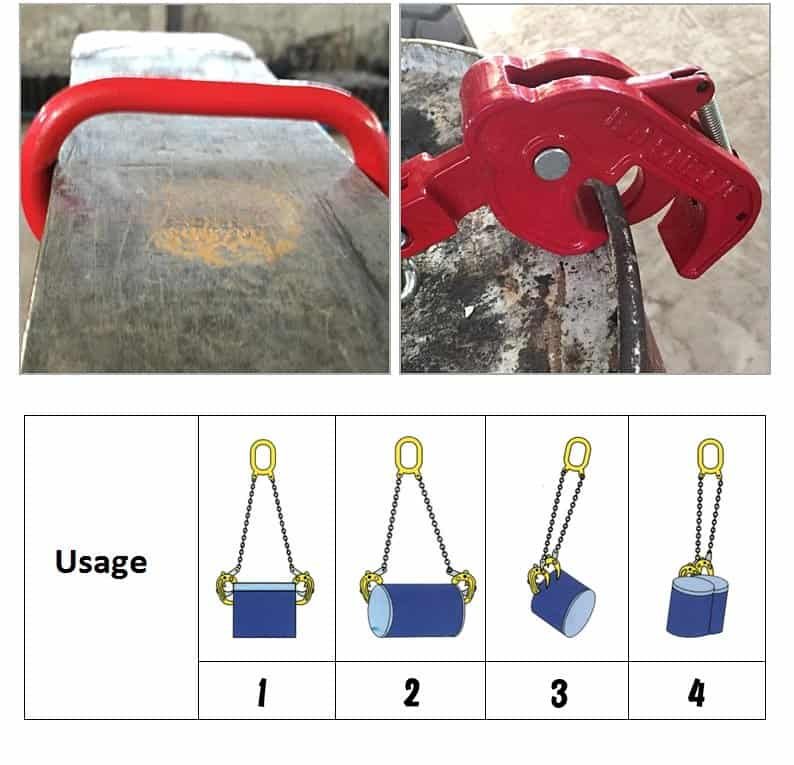

SL Drum Clamp

- With an automatic locking mechanism

- The SL steel drum clamps can be used singly or in pairs.

- Avoid snatch or shock loading

- Clamps firmly on a 2-leg grade chain sling.

WLL: 1T, Jaw Opening: 0-25mm

LR/LH Drum Clamp

- Vertical drum clamp( for drums with a lid)

- Horizontal drum clamp( for drums without a lid)

- Main body made of high tensile steel with welded construction that is resistant to cracks

- Safety factor: 5:1

- Standard: AS4991-2004

Capacity: 500kg, drum size: 200L

Typical applications:

- Chemical plants (liquid raw materials)

- Warehousing (oils, coatings, food products)

- Ports and logistics hubs

How to Choose the Right Clamp?

Step 1: Confirm object size and weight

- Pipes: diameter, length, wall thickness

- Drums: capacity (200L/100L), material (steel/plastic)

Step 2: Define your task

- Only lifting → standard pipe clamp or vertical drum clamp

- Lifting + stacking → horizontal drum clamp

- Lifting + tilting → drum tilting clamp

Step 3: Check equipment compatibility

- Forklift, hoist, or crane interface

- Need for quick attachment change

Safety and Maintenance Tips

Pre-use inspection: Check jaw wear, pins, and moving parts

During lifting: Keep vertical force, avoid side pulling

Safety zone: Never stand under suspended loads

Regular maintenance: Lubricate moving parts, perform periodic load tests

Storage: Avoid long-term exposure to moisture and corrosive environments

Frequently Asked Questions (FAQ)

Q1: Can a clamp grip securely on rough concrete surfaces?

A: Yes. The arc-shaped jaw design is made for rough surfaces, but keep the jaws clean to avoid slipping.

Q2: Can a drum clamp handle plastic drums?

A: Yes, but a drum clamp designed for plastic drums should be used to avoid barrel deformation.

Q3: Can a drum clamp be used for concrete pipes?

A: Not recommended. Drum clamps don’t have enough load capacity or the right jaw shape for pipes.

Q4: Can one clamp handle different pipe diameters?

A: Adjustable models cover a certain diameter range, but outside this range a new clamp is required.

Q5: Do drum tilting clamps require two operators?

A: Most models can be operated by one person, but for hazardous liquids two operators are safer.

Conclusion

- If your work involves construction site pipe handling → choose a concrete pipe clamp.

- If you need to handle, stack, or tilt drums → choose a drum clamp.

评论

发表评论