What is a Hand Cable Winch?

A hand cable winch is a mechanical device that uses a manual crank to drive gears and a drum to pull or release a steel cable or synthetic rope. It is commonly used for towing, hauling, and lifting light loads, such as boats, trailers, or construction materials. Compared to electric winches, hand winches are simple, portable, and cost-effective, but require human effort to operate.

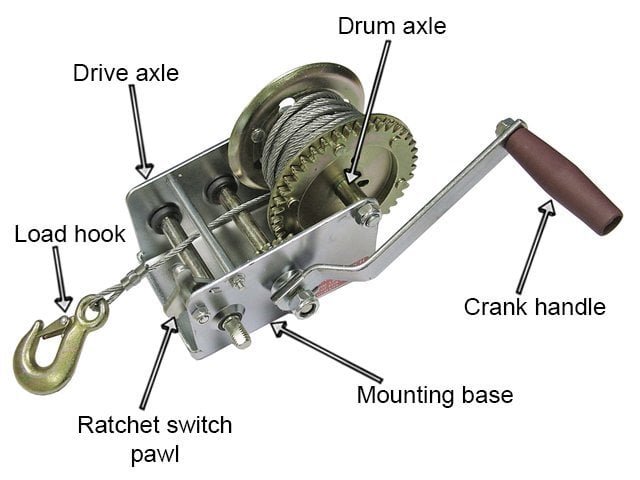

What are the parts of a cable winch?

Drum Alex: The spool for winding the steel cable or rope. When the handle is turned, both the drive axle and drum axle rotate simultaneously, causing the drum to turn as well.

Drive Axle: The winch is operated by turning the handle, which rotates the central drive axle. The axle then transmits motion to the locking mechanism and gears, which drive the drum to spool the cable.

Load Hook: The load hook is attached to the cable, which is secured to the object intended for movement or pulling.

Ratchet Switch Pawl & Brake: The ratchet switch pawl has the flexibility to be positioned either up or down, engaging with the gear on the drive axle. When in the up position, the winch can wind and pull or move an object. Conversely, placing the pawl in the down position facilitates the unwinding of the cable.

Crank Handle: Manual operation for pulling or releasing loads.

Mounting Base: Secures the winch to a surface or vehicle.

How a Hand Winch Works?

A hand winch is a manually operated tool for lifting and pulling. At its core, a gear mechanism converts the circular motion of the handle into a linear force. This action either retracts the cable onto the drum or pulls the load, depending on the direction of rotation.

It works through a crank → gear system → drum → cable transmission that amplifies force.

Common Problems and Solutions

Even with regular maintenance, a hand cable winch may encounter certain issues. Understanding these problems and their fixes ensures safe and efficient operation:

- Cable Slipping

- Cause: Uneven winding, worn-out cable, or exceeding rated load.

- Solution:

- Rewind the cable neatly on the drum.

- Inspect for frayed or stretched cable and replace if necessary.

- Double-check that the load is within the winch’s rated capacity.

- Crank Difficult to Turn

- Cause: Lack of lubrication, rusted gears, or damaged pawl.

- Solution:

- Apply appropriate grease or oil to gears and bearings.

- Remove any rust with a wire brush and re-lubricate.

- Inspect the pawl mechanism; replace if bent or excessively worn.

- Brake Failure

- Cause: Worn brake pads, oil contamination, or spring fatigue.

- Solution:

- Inspect and replace worn brake pads immediately.

- Clean off oil or grease from the braking surface.

- Check the return spring; replace if it no longer provides sufficient tension.

- Unusual Noise During Operation

- Cause: Loose bolts, misaligned gears, or lack of lubrication.

- Solution:

- Tighten all bolts and fasteners.

- Realign gears if they show uneven wear.

- Lubricate moving parts to reduce friction.

- Drum Not Holding Load

- Cause: Damaged pawl or broken ratchet teeth.

- Solution:

- Inspect the ratchet wheel and pawl for cracks or missing teeth.

- Replace defective components immediately before further use.

How to install and operate the hand cable winch?

- Confirm the mounting surface is sturdy.

- Secure the winch base with bolts or brackets.

- Evenly wind the cable onto the drum.

- Attach the hook securely to the load.

- Turn the crank clockwise to tighten; keep your body stable while operating.

- After use, fully retract the cable to prevent tangling.

Safety Tips

- Never overload or use it for lifting people.

- Keep the cable neatly wound to avoid kinks or overlapping.

- Keep hands and clothing away from gears during operation.

- Avoid side pulls or angled loads to prevent tipping.

- Inspect for wear or damage before use.

Frequently Asked Questions (FAQ)

Q1: Can a hand winch replace an electric winch?

A: Suitable for light loads and occasional use. For heavy or frequent work, electric winches are recommended.

Q2: Steel cable or synthetic rope—which is better?

A: Steel cables are stronger and more durable; synthetic ropes are lighter and safer for personal use.

Q3: Can it be used for lifting?

A: Absolutely not. Hand winches are only for moving cargo.

To summarize, a hand cable winch is a proven,valuable asset for efficient towing and hauling. Success depends on correct selection based on key factors like load capacity, material durability, and brake functionality, followed by safe operating practices.

评论

发表评论