Safety harnesses are vital for protecting workers during high-risk tasks like construction, climbing, or working at heights. Whether on a job site or an outdoor adventure, picking the right harness can prevent injuries and improve comfort.

Key components of a safety harness

Straps and Webbing: These form the structure of the harness, typically made from durable materials like nylon or polyester. The straps go over the shoulders, around the waist, and sometimes between the legs.

D-Rings and Attachment Points: These are located at various points on the harness and are where you connect fall arrest systems (such as a lanyard or lifeline).

Buckles and Adjustments: Used to ensure a proper and comfortable fit. Proper adjustability is essential for the harness to function correctly and safely.

Function of a Safety Harness:

- Fall Protection: In case of a fall, the harness is designed to stop the fall and distribute the forces across the body, reducing the risk of injury.

- Work Positioning: It allows workers to stay in place while performing tasks, especially in environments like scaffolding, rooftops, or towers.

- Confined Space Rescue: In certain industries, a safety harness is used to retrieve individuals from dangerous or hard-to-reach areas.

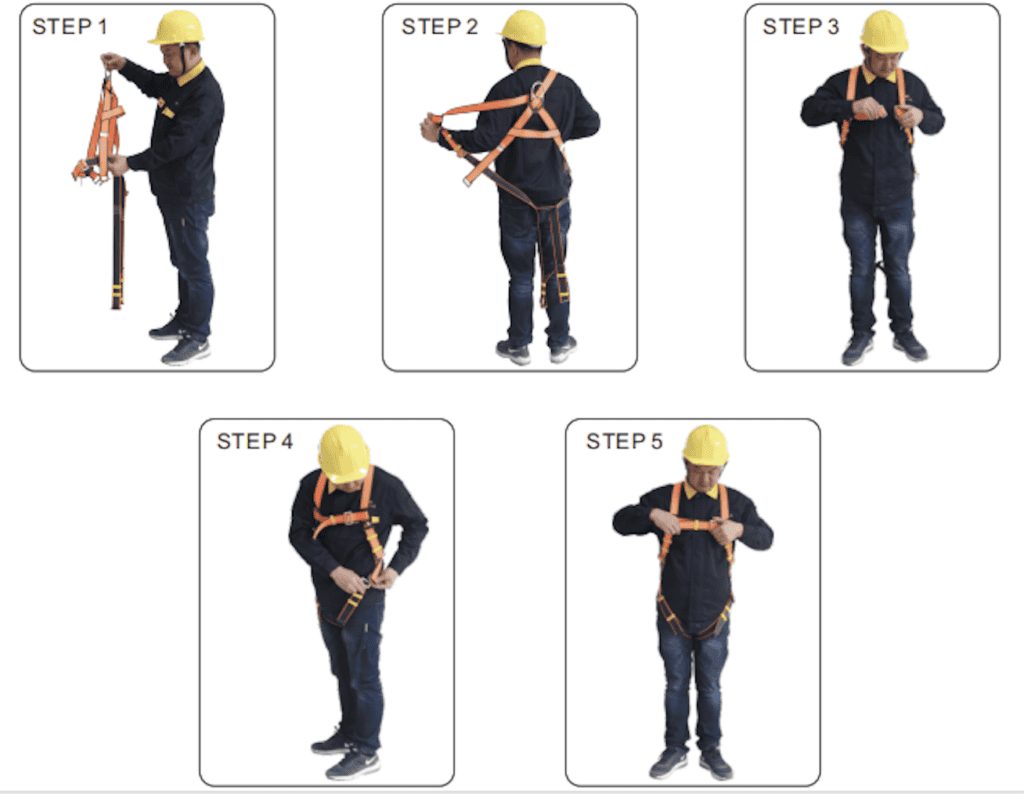

How to use a safety harness?

Using a safety harness correctly is just as important as choosing the right one. Here are the basic steps for proper use:

- Inspection: Before every use, inspect the harness for wear and tear. Check the straps, buckles, D-rings, and stitching. Look for signs of fraying, tears, or damage that could compromise its integrity.

- Putting it On: Don’t rush when putting on your harness. Ensure all straps are adjusted to fit snugly yet comfortably. The harness should be snug around the waist and chest but should allow for full movement.

- Attachment: Always ensure that the harness is correctly attached to a secure anchor point or fall protection system. Double-check all connections to avoid accidents.

- Proper Fit: A harness that fits poorly is as dangerous as no harness at all. Straps should be snug enough to prevent slipping, but not so tight that they dig into your skin. The harness should fit comfortably, with the chest strap at sternum level.

How much weight can your safety harness support?

The weight capacity of a safety harness generally depends on its design, materials, and purpose. Most safety harnesses are built to support a specific range of body weight, along with any additional gear or equipment being carried.

OSHA: The Occupational Safety and Health Administration (OSHA) requires that personal protective equipment, including safety harnesses, must be able to support at least 5,000 pounds (2,268 kg) of force in the event of a fall.

ANSI: The American National Standards Institute (ANSI) also sets similar requirements for strength, ensuring that the harness and its components can handle significant impact forces.

EN Standards: European safety standards (EN 361) also specify strength requirements for fall arrest systems, ensuring the harness can withstand the forces exerted during a fall.

Maintenance Tips for the Safety Harness

To keep your safety harness reliable and long-lasting, follow these key maintenance steps:

1. Regular Inspections

- Check for fraying, cuts, or burns on straps before each use.

- Ensure buckles, D-rings, and stitching are secure and undamaged.

- Replace immediately if any webbing is torn or weakened.

2. Proper Cleaning

- Hand wash with mild soap and water (avoid bleach or harsh chemicals).

- Air dry—never use heat (dryers, radiators, or direct sunlight).

- Never iron or soak the harness for long periods.

3. Correct Storage

- Keep in a cool, dry place, away from sunlight and moisture.

- Avoid contact with chemicals, sharp objects, or extreme temperatures.

4. Repairs & Replacement

- Never fix with tape or glue—replace damaged parts immediately.

- If the harness absorbs a fall impact, retire it even if it looks fine.

A well-maintained harness ensures maximum safety—never risk using a damaged one!

Conclusion

A safety harness is a crucial piece of equipment for anyone working at heights, climbing, or engaging in high-risk activities. Understanding the types of harnesses, safety standards, key features, and how to use them properly will help you make an informed decision.

评论

发表评论