Regarding bundling and transporting goods, the Cam Buckle strap stands out as a preferred tie-down tool for many users due to its simple operation and lightweight design. In this article, we’ll explore what a cam buckle is, its advantages and disadvantages, common applications, and tips for choosing the right product.

What is the cam buckle?

A cam buckle is a tie-down device that uses an internal spring-loaded mechanism to grip the strap. It’s commonly used with polyester webbing in widths like 25mm and 38mm. To use it, simply feed the webbing through the cam buckle and pull it tight. The spring-loaded buckle automatically clamps down, securing the load without the need for complex steps.

Pros and Cons of Cam Buckles

Pros:

- Easy to operate: Requires little effort to secure the load.

- Lightweight and compact: Easy to carry and store.

- Cost-effective: Affordable and suitable for home or light-duty use.

- Quick tension and release: Ideal for tasks requiring frequent adjustments.

Cons:

- Limited load capacity: Not suitable for heavy-duty loads or industrial use.

- Lower gripping force: May loosen under intense vibration.

Cam Buckle Strap vs. Ratchet Strap

| Features | Cam Buckle | Ratchet Strap |

| Operation | Manual Pull with spring clamp | Ratcheting mechanism for tightening |

| Application | Light loads, home use, short hauls | Heavy loads, long hauls, high-tension needs |

| Ease of Use | Very easy | Slightly more complex |

Cam buckle types and Patamteres

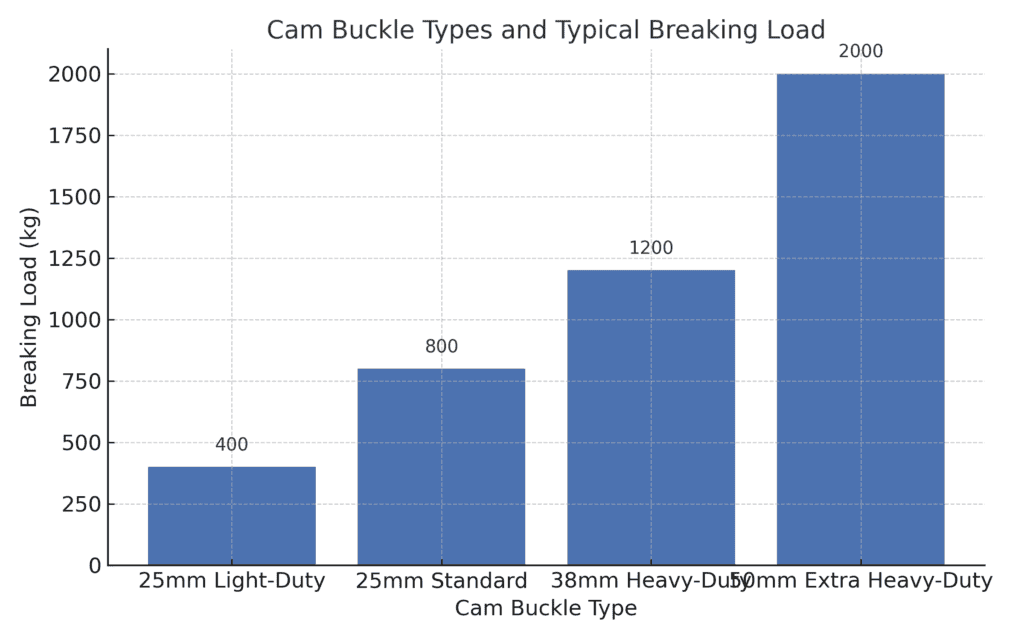

When choosing the right cam buckle strap, understanding the different types and their breaking loads is essential to ensure safety and performance. Light-duty 25mm cam buckles typically support up to 250kg, 350kg, 400kg, making them ideal for household or light transport needs. For more demanding tasks, 25mm standard versions offer up to 500kg, while 38mm heavy-duty options can handle 900kg. For industrial-grade applications, 50mm extra heavy-duty cam buckles provide a robust breaking load of up to 2,000kg. Always choose a cam buckle strap based on your specific load requirements to prevent slippage or failure under tension.

How to Properly Use a Cam Buckle Strap?

- Feed the loose end of the strap through the cam buckle.

- Pull the strap to tighten and secure your load.

- To release, press the buckle’s release button and loosen the strap.

Important Notes:

- Do not use for loads that exceed the rated capacity.

- Avoid contact with sharp edges that may cut the webbing.

- Keep the buckle and webbing clean to prevent slippage.

Common Applications for Cam Buckle Straps

- Securing moving boxes during relocation

- Fixing luggage during road trips

- Tying down outdoor gear (e.g., tents, folding tables and chairs)

- Securing small items on car roofs or shelves

Frequently Asked Questions (FAQ)

Q: Can cam buckle straps be reused? A: Yes, as long as the strap and buckle are undamaged, they can be reused multiple times.

Q: Can I use it to secure a motorcycle? A: Not recommended. For motorcycles or heavy-duty transport, ratchet straps are more appropriate.

Q: Do cam buckles slip easily? A: Not if used within the rated load range, but avoid oil, dirt, or significant wear that may reduce grip.

www.chinatoplifting.com

tracy@chinatoplifting.com

评论

发表评论