How to avoid and fix common mistakes when using ratchet straps?

Ratchet straps are essential tools for securing cargo during transport. Whether you're tying down goods on a truck, securing a motorcycle or machinery, they help ensure safety, prevent damage, and reduce liability risks.

But here’s the truth: many users often make small mistakes that can lead to big problems—from cargo shifting to strap failure.

In this blog, we’ll cover 6 of the most common ratchet strap mistakes and how you can avoid them to stay safe and extend the life of your straps.

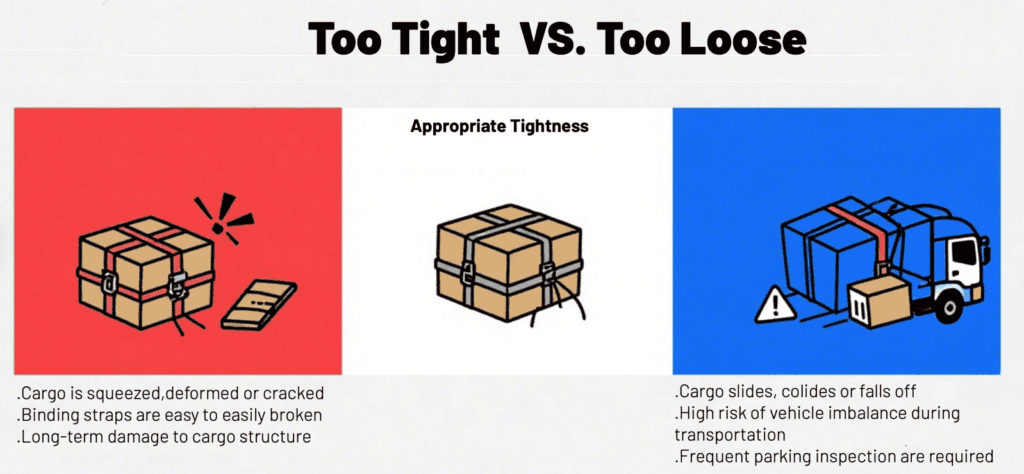

Mistake 1: Strapping Too Loose or Too Tight

What’s the problem?

- Too loose? Cargo may shift, get damaged from friction, or even fall off during transport.

- Too tight? You risk crushing your cargo, overstressing the strap or hardware, and reducing its lifespan.

Practical tip: If you press down on the cargo with both hands and it doesn’t move, the tension is about right.

Mistake 2: Tying Knots or Wrapping the Strap

What’s the problem?

- Knots create stress concentration points, reducing strap strength.

- Wrapping the strap can cause the ratchet to slip or fail to tighten properly.

Correct way:

- If the strap is too long, use a strap winder or fold the excess neatly—never tie knots.

- Better yet, choose a strap with the appropriate length and secure any excess with a band or Velcro tie.

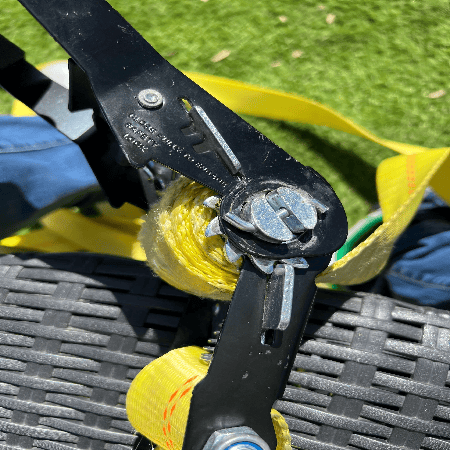

Mistake 3: Using Rusty, Cracked, or Deformed Hardware

What’s the problem?

- Rusted or cracked hooks and ratchets lose strength and may break under tension.

- Deformed or jammed hardware may not lock or release properly, creating a safety hazard.

If you notice rust, cracks, or hard-to-move parts, replace them immediately.

Mistake 4: Ignoring Strap Wear, Fraying, or Contamination

What’s the problem?

- Long-term use, UV exposure, or chemical contact weakens the webbing.

- Oil, dirt, or grit can reduce friction and increase the risk of slipping.

Correct way

Keep the straps dry and away from chemicals or direct sunlight.

If you see frayed edges, trim and heat-seal them, or replace the strap if severely damaged.

Mistake 5: Incorrect Locking Direction or Improper Tensioning

What’s the problem?

- If the ratchet faces the wrong way, tension may be reversed, leading to slippage.

- Fixing only one side may cause uneven force and make the load unstable.

Correct way:

- Always face the ratchet toward the load to ensure proper tensioning.

- Use an “X” cross pattern to distribute force evenly and stabilize the load.

Mistake 6: Not Locking the Ratchet or Securing the Strap Tail

What’s the problem?

- If the ratchet isn’t fully locked, it can loosen during the trip.

- Loose strap tails can flap in the wind, wear out quickly, or even get caught in moving parts.

Correct way:

- After tightening, make sure the ratchet handle is fully locked into position.

- Roll up the extra strap tail and secure it with a tie or Velcro strap.

Proper Use + Regular Checks = Safe Transport!

Using ratchet straps correctly isn’t just “tighten and forget.” Don’t let small mistakes cost you big! Make sure you’re using your ratchet straps correctly and safely every time.

www.chinatoplifting.com

tracy@chinatoplifting.com

评论

发表评论